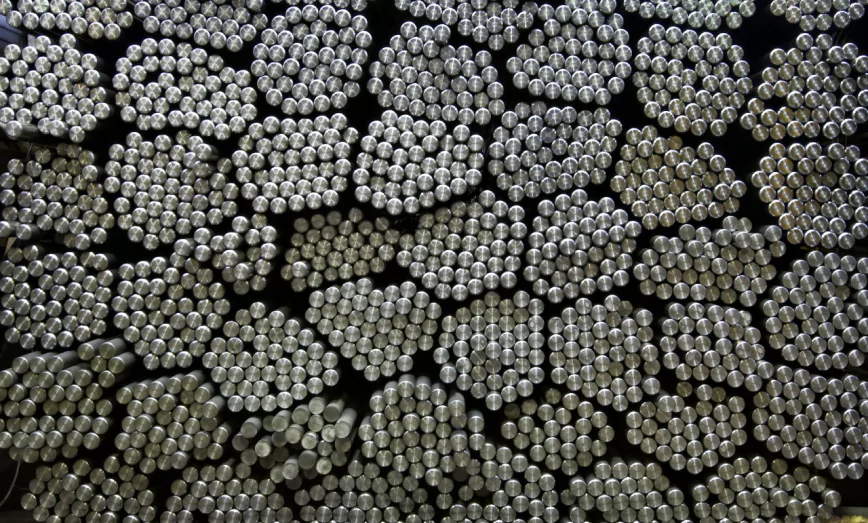

Laser Tube Cutting

Our Lasertube LT8 utilizes Fiber Laser technology to process round, square, rectangular, and special-shaped tubes, as well as angle iron, channel, and flat bar. It is essential for intricate joints and kits for the automotive, medical, construction, and energy industries, delivering unparalleled productivity and 3-D machining capability.